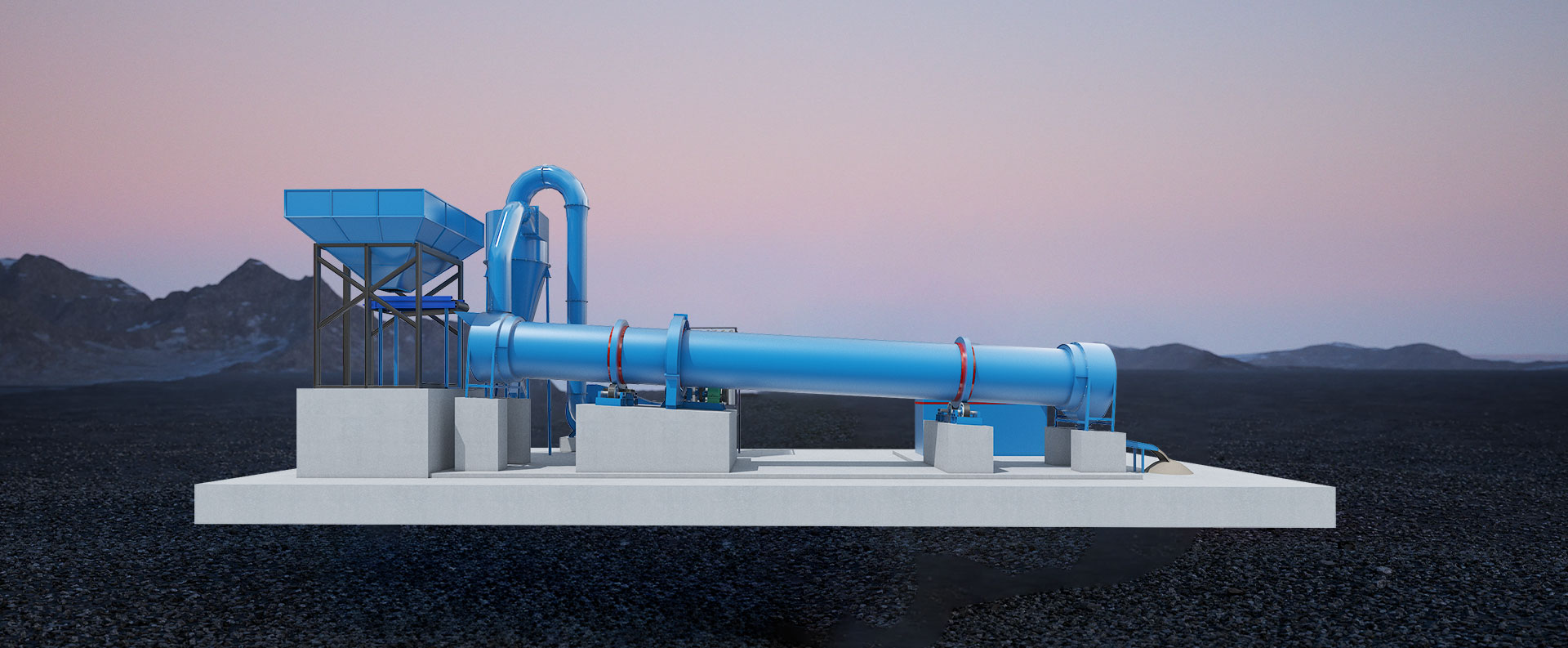

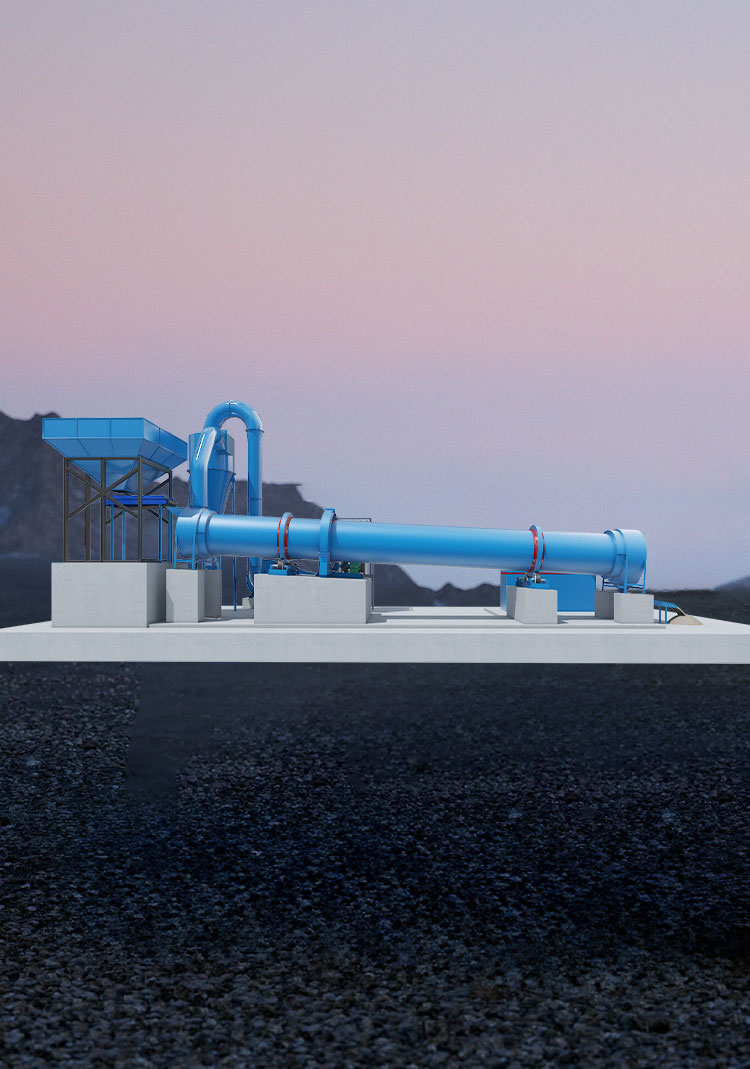

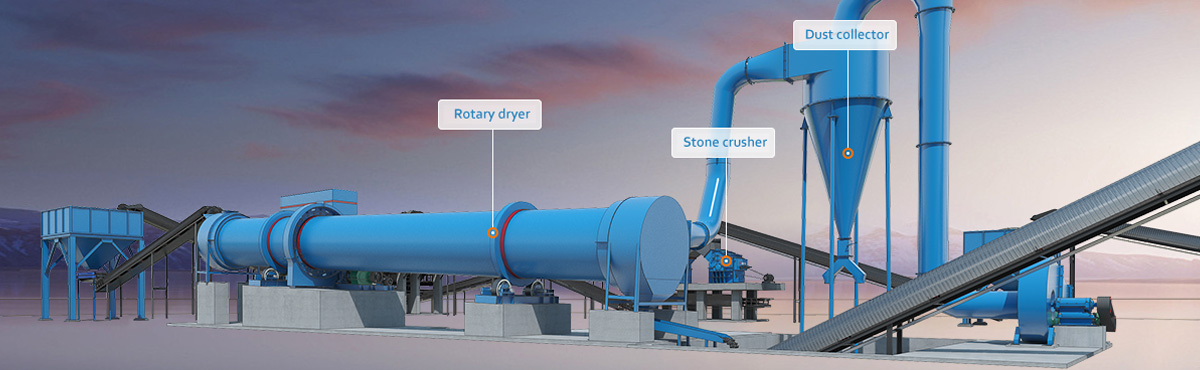

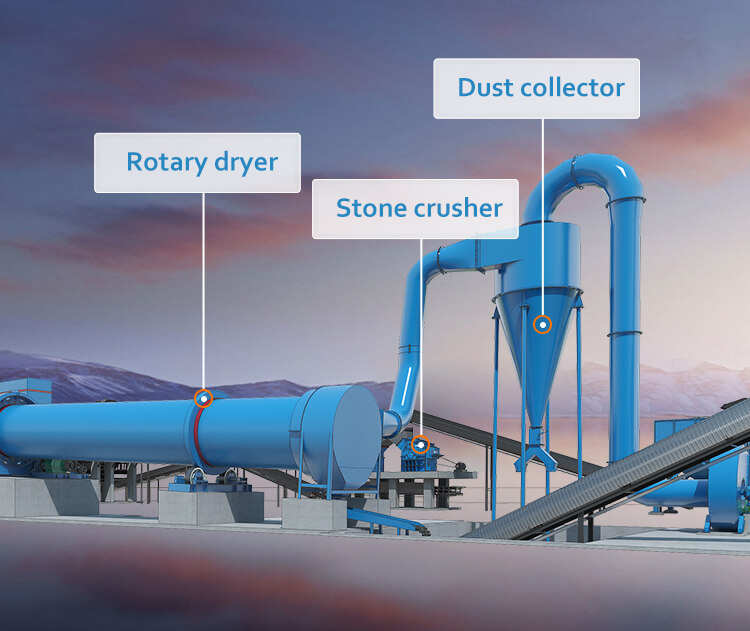

FTM rotary dryer can continuously and efficiently dry various materials. It has the advantages of large output, small footprint, low energy consumption, stable operation and environmental protection. The whole drying system is flexible and can be configured with supporting systems such as feeding and discharging, heat source, transportation, dust removal, discharging and packaging according to customer requirements. It can be widely used in drying needs of various industries. Users can customize the dryer according to their own needs.

Rotary Dryer

1.9-76t/hProcessing capacity

9-285m³Cylinder capacity