-

Core equipment:

feeder,

jaw crusher,

vibrating screen,

ball mill,

spiral chute,

shaking table,

dryer.

The gravity separation gold ore beneficiation line mainly includes four processes:

crushing and screening, grinding, gravity separation, and drying.

Stage 1: Crushing and Screening

The primary crushing process uses a coarse jaw crusher to coarsely crush large gold ore.

The discharge is conveyed by a belt conveyor to a fine jaw crusher for secondary crushing.

Qualified discharge is sent to a transfer silo; otherwise, it undergoes secondary crushing.

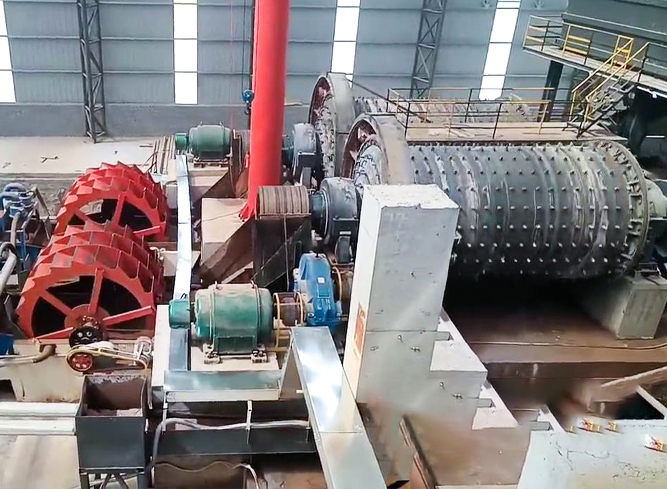

Stage 2: Grinding

Ore with a particle size less than 25mm is evenly fed to a ball mill by a belt conveyor for wet grinding.

The slurry from the ball mill passes through a spiral classifier, and the larger particles are fed back to the mill for further grinding.

The finely processed slurry flows into a slurry pool for standby use.

Stage 3: Gravity Separation

The slurry from the slurry pool is mixed in a mixing tank and then pumped by a slurry pump to a spiral chute for classification.

It is then pumped to multiple shaking tables for gravity separation, resulting in finished gold concentrate.

Stage 4: Drying

Gold concentrate with a relatively high water content is dried in a dryer to produce gold powder.

-

Get the Latest Quote